Hey guys,

New to this site but you guys seem awesome and informative!

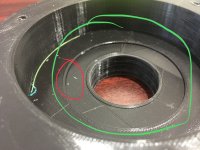

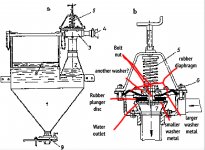

I am trying to build (3d print) a pan American pulse jig but I am not getting a pulse.

I have tried many designs, many different diaphragms plungers etc.. but can't get a pulse! =/

I will take a pic and let me know your thoughts please.

New to this site but you guys seem awesome and informative!

I am trying to build (3d print) a pan American pulse jig but I am not getting a pulse.

I have tried many designs, many different diaphragms plungers etc.. but can't get a pulse! =/

I will take a pic and let me know your thoughts please.