lamar

Bronze Member

- Aug 30, 2004

- 1,341

- 46

Why not make a "roll-yer-own" 2.5 dredge/power sluice/hi-banker combo rig?

Dear group;

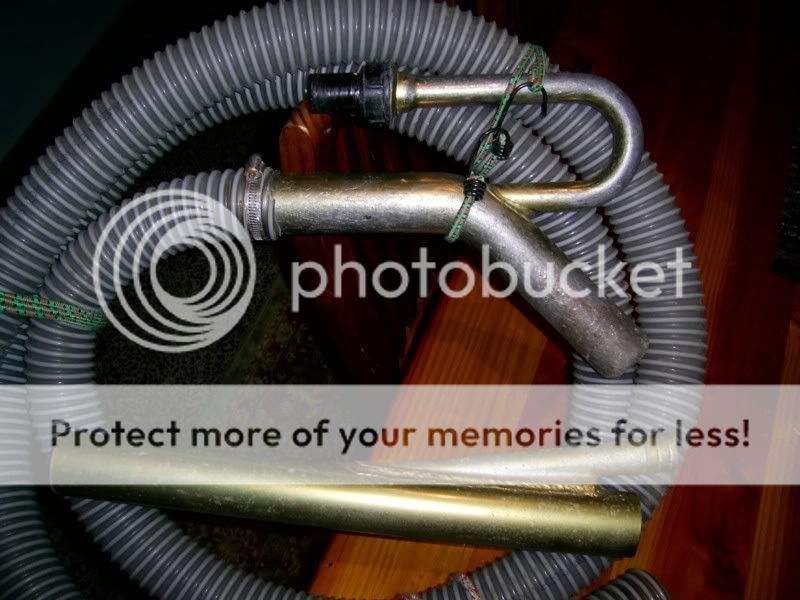

I decided to build my own 2.5" dredge/power sluice/hi-banker combo rig. Here are some pix of the flare, the suction nozzle and the sluice box without the riffle bar assembly. The material used for the flare is 2.5" dia. 1/6" thick exhaust pipe and the plate and flange is 1/16" cold rolled steel. The suction nozzle is the same 2.5" material with a 1.25" dia. by 1/16" thick tube material. The small pipe between the 2.5" piece and the 1.25" piece is just a brace support and it adds rigidity to the 1.25" pipe. The sluice box is 10" wide and 36" long and is constructed from 12 gauge galvanized steel. Inside of it is the green nomad matting and a piece of 1/2" rubber diamond shaped matting.

I will post more pix when I get the riffle bar assembly and flare-to-sluice junction made.

Your friend;

LAMAR

Dear group;

I decided to build my own 2.5" dredge/power sluice/hi-banker combo rig. Here are some pix of the flare, the suction nozzle and the sluice box without the riffle bar assembly. The material used for the flare is 2.5" dia. 1/6" thick exhaust pipe and the plate and flange is 1/16" cold rolled steel. The suction nozzle is the same 2.5" material with a 1.25" dia. by 1/16" thick tube material. The small pipe between the 2.5" piece and the 1.25" piece is just a brace support and it adds rigidity to the 1.25" pipe. The sluice box is 10" wide and 36" long and is constructed from 12 gauge galvanized steel. Inside of it is the green nomad matting and a piece of 1/2" rubber diamond shaped matting.

I will post more pix when I get the riffle bar assembly and flare-to-sluice junction made.

Your friend;

LAMAR

Amazon Forum Fav 👍

Attachments

Upvote

0

To build the flare, I did this:

To build the flare, I did this: