SaltwaterServr

Sr. Member

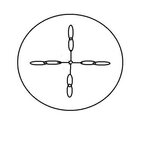

I had a flail crusher drop into my lap this weekend for a price I couldn't pass up. I got to thinking as I'm planning some mods to it, why don't folks run 4 flails instead of just two? You'll get twice as much life on your chains and if you have a double digit hp motor, it should put out enough torque.

One of the reasons I can see is starting the engine without an idle pulley on it would be tough. Second you'd most likely need twin belt pulleys too. A little weight difference but considering the weight already, 10-12 extra pounds is worth double the time between chain switch outs.

Any thoughts on it?

One of the reasons I can see is starting the engine without an idle pulley on it would be tough. Second you'd most likely need twin belt pulleys too. A little weight difference but considering the weight already, 10-12 extra pounds is worth double the time between chain switch outs.

Any thoughts on it?