SaltwaterServr

Sr. Member

Now that I've found the mine I'm going to work on, the academic questions have become practical application questions. The one I'm working through right now is getting the rehab started and the waste rock out of the mine.

I've got a few ideas swirling around my head.

The adit is pretty narrow as you might have seen in the video.

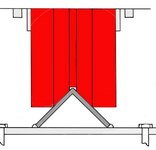

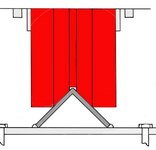

I've considered building a front-dump ore car using either v-groove swivel casters or flanged swivel casters.

The flanged I can run on 2" pipe.

The swivel v-groove I can run on 2x2x1/4" angle iron.

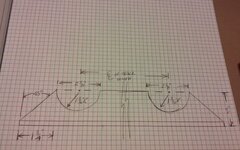

The v-groove is better choice because angle iron is cheaper than pipe. It's also easier to weld a piece of flat bar across the toes of the angle to make a mounting to bolt down to the cross-ties like this:

The saving grace about pipe is that it's a lot easier to bend it to make it around corners, but I only have one corner in the adit so far.

I can also buy an old riding lawnmower to pull the car through the mine. I already have the ventilation issue worked out, so no worries about that. With the deep V riding on the angle, I should also be able to back the empty car down the adit. Also, I can decouple the car outside from the mover and push it back in. The two sets of alcoves should give me room to turn the mower to pull the car back out again when full. Additionally, I can completely board over the winze and turn it around there.

The third and cheaper option is a two-wheeled wheelbarrow. Good to start with, easy to dump, cheap. Problem is pushing it across the existing cross ties and waste rock on the adit sill.

Fourth option, a pre-built cart like this that can haul up to a ton and a half of rock:

https://www.uline.com/Product/Detail/H-2548/Carts-Dollies/Wagon-Cart-30-x-60

I can get some 1/8" steel sheet and build sides for it to make it a box. Also I can modify the frame a bit and make it into a side dump car. I can use chain around the handle to tie it to the lawn mower to pull it out or make a mounting bracket for the mower. It will have to be pushed back into the mine by hand since there won't be any guides for the wheels.

I could conceivably take off the pneumatic tires and put v-casters on it to be able to run it back and forth with the lawn mower. The big plus though is being able to use the wagon cart without the need to install any kind of guide track on the sill.

If folks have any other ideas, let me know.

I've got a few ideas swirling around my head.

The adit is pretty narrow as you might have seen in the video.

I've considered building a front-dump ore car using either v-groove swivel casters or flanged swivel casters.

The flanged I can run on 2" pipe.

The swivel v-groove I can run on 2x2x1/4" angle iron.

The v-groove is better choice because angle iron is cheaper than pipe. It's also easier to weld a piece of flat bar across the toes of the angle to make a mounting to bolt down to the cross-ties like this:

The saving grace about pipe is that it's a lot easier to bend it to make it around corners, but I only have one corner in the adit so far.

I can also buy an old riding lawnmower to pull the car through the mine. I already have the ventilation issue worked out, so no worries about that. With the deep V riding on the angle, I should also be able to back the empty car down the adit. Also, I can decouple the car outside from the mover and push it back in. The two sets of alcoves should give me room to turn the mower to pull the car back out again when full. Additionally, I can completely board over the winze and turn it around there.

The third and cheaper option is a two-wheeled wheelbarrow. Good to start with, easy to dump, cheap. Problem is pushing it across the existing cross ties and waste rock on the adit sill.

Fourth option, a pre-built cart like this that can haul up to a ton and a half of rock:

https://www.uline.com/Product/Detail/H-2548/Carts-Dollies/Wagon-Cart-30-x-60

I can get some 1/8" steel sheet and build sides for it to make it a box. Also I can modify the frame a bit and make it into a side dump car. I can use chain around the handle to tie it to the lawn mower to pull it out or make a mounting bracket for the mower. It will have to be pushed back into the mine by hand since there won't be any guides for the wheels.

I could conceivably take off the pneumatic tires and put v-casters on it to be able to run it back and forth with the lawn mower. The big plus though is being able to use the wagon cart without the need to install any kind of guide track on the sill.

If folks have any other ideas, let me know.