Re: Can we build it? Wood furnace day one-three.

Hard decision sis! I say pray hard the rest of the pipe is in before the weekend because no way you can get Gerry and the boys to agree to hurry up and wait now....cuz....well this just might work....gotta get it done so we can see!

COUNTRY GIRL said:It will have some frustration.......the rest of the black iron pipe may or may not be in for the weekend....start another step and risk an error.....or hurry up and wait? This just might work!

Hard decision sis! I say pray hard the rest of the pipe is in before the weekend because no way you can get Gerry and the boys to agree to hurry up and wait now....cuz....well this just might work....gotta get it done so we can see!

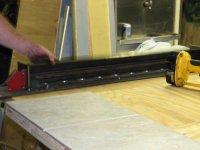

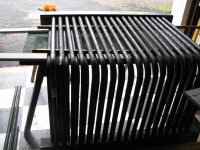

Ty and I kept switching on who got to hold the pipe. We have the look down pat!

Ty and I kept switching on who got to hold the pipe. We have the look down pat!  Then we made sure it was a perfect fit, took it back apart, cleaned it up, ready for welding tomarrow.

Then we made sure it was a perfect fit, took it back apart, cleaned it up, ready for welding tomarrow.

Funny we kept joking about how it was going to be a leaker.

Funny we kept joking about how it was going to be a leaker.