restless spirit

Full Member

just kicking around the idea of making a sluice. and wonder what some guys use other than a big metal brake...

, so let me know if it's actually turning out as jibberish! Hmm...spell cheak says jibberish should be gibberish, but I was raised using a "J", so there!!

, so let me know if it's actually turning out as jibberish! Hmm...spell cheak says jibberish should be gibberish, but I was raised using a "J", so there!!

Look for local plastic suppliers in your area online. Mine runs about $80. for a 1/4" 4'x8' sheet. You can easily use it for flairs, leg brackets, crash boxes....your imagination and creativity are the only limit. It can be bolted, threaded or even glued/welded with common abs pipe cement. If you worry about wear in crash boxes and such, it can be lined with rubber sheet or uhmw to protect the plastic. You could even make a vacuform set up if you so desire. There's lot's of videos on youtube and diy websites like this one: Homemade Tools Categories

It's the same stuff BGT's are made of.

Have fun, it's addictive and fun to use.

Lightly oil the brake prior to heating plastic sheet. That way you avoid any possibility of the plastic getting too hot and sticking to the metal.

If the abs melts to the point it will stick. it is too hot. Do not put oil on prospecting gear.

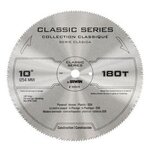

You can get by with a plywood blade, but they also make blades for plastic. You're looking for shallow hook (tooth angle) and many teeth to prevent taking too much with a single tooth.I found the supplier for abs sheet (and all other types too) in Tucson is a plastics fabrication facility. A couple of years ago I had them cut and bend my abs sluice (I used Goldhog mats) but now I am thinking of building another one myself. Here comes the question.....I would rather cut and glue/cement rather than bend so what do you use to cut the abs and if it is a table or skilsaw then what type of blade do you use? I assume a router will work too.

Thanks