Capt Nemo

Bronze Member

Just finished building Bucket Buddy II. On this version, I changed the dam angle from 90 to 60 degrees and dropped one spraybar.

On the last version, I was loosing gold to both displacement and not having area to let the gold settle. I took a look at the diagram for a Graffe's E-tank (Keene Hydromatic Jig) and found it similar to my active fluid beds. On the E-tank, the bed has 60 degree sides that give room for the gold to settle away from the active center, and the sides force a slow subsidence of material down to the active center. In the first version, the active area was right up to the dam, and the fine gold could rise and get dumped on the spillway and be lost. The displacement was also a problem, as a spoonful of solid material would push fluid material up and over the dam. Fine gold in the active part of the bed will fly around like glitter in a hurricane, so it's constantly circulating in the bed. It's just too light to settle on the bottom of the bed and stay put. So I angled the dam away from the active area to provide a dead zone where the gold can settle without getting pushed over the dam.

The Graffe's E-tank design has been tested and is capable of capturing 93% at #400. So we'll see what happens with this one. I'm headed out tomorrow to grab some beach sand for testing.

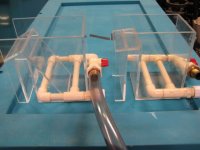

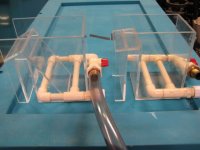

Here's the Bucket Buddy II next to the original.

Here's a shot of the bottom.

And hanging on a bucket.

On the last version, I was loosing gold to both displacement and not having area to let the gold settle. I took a look at the diagram for a Graffe's E-tank (Keene Hydromatic Jig) and found it similar to my active fluid beds. On the E-tank, the bed has 60 degree sides that give room for the gold to settle away from the active center, and the sides force a slow subsidence of material down to the active center. In the first version, the active area was right up to the dam, and the fine gold could rise and get dumped on the spillway and be lost. The displacement was also a problem, as a spoonful of solid material would push fluid material up and over the dam. Fine gold in the active part of the bed will fly around like glitter in a hurricane, so it's constantly circulating in the bed. It's just too light to settle on the bottom of the bed and stay put. So I angled the dam away from the active area to provide a dead zone where the gold can settle without getting pushed over the dam.

The Graffe's E-tank design has been tested and is capable of capturing 93% at #400. So we'll see what happens with this one. I'm headed out tomorrow to grab some beach sand for testing.

Here's the Bucket Buddy II next to the original.

Here's a shot of the bottom.

And hanging on a bucket.