Load77

Jr. Member

I have a good jaw crusher that’s mounted on a frame with two big metal i-beams.

I’d like to build a roller crusher below it to reduce it to 1/8”- to feed my ball mill with.

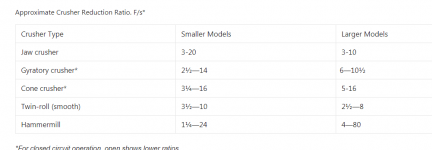

My question is, what is a good size reduction ratio for a roller crusher? The quartz comes out of my jaw crusher at about 1”-. Will I need more than one set of rollers to reduce it to 1/8”-?

I’ve never seen a roller crusher in action, so I’m not familiar with what they’re capable of.

Thanks for any help!

I’d like to build a roller crusher below it to reduce it to 1/8”- to feed my ball mill with.

My question is, what is a good size reduction ratio for a roller crusher? The quartz comes out of my jaw crusher at about 1”-. Will I need more than one set of rollers to reduce it to 1/8”-?

I’ve never seen a roller crusher in action, so I’m not familiar with what they’re capable of.

Thanks for any help!

Let me know how it goes I have been thinking about a roller crusher as well.

Let me know how it goes I have been thinking about a roller crusher as well.