Charlie P. (NY)

Gold Member

- Joined

- Feb 3, 2006

- Messages

- 13,021

- Reaction score

- 17,188

- Golden Thread

- 0

- Detector(s) used

- Minelab Musketeer Advantage Pro w/8" & 10" DD coils/Fisher F75se(Upgraded to LTD2) w/11" DD, 6.5" concentric & 9.5" NEL Sharpshooter DD coils/Sunray FX-1 Probe & F-Point/Black Widows/Rattler headphone

- Primary Interest:

- Metal Detecting

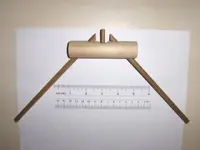

When I added the Sunray FX-1 pinpointer to my F75 detector I would invariable topple the works over when pinpointing. I set about to come up with a simple and light stand that would allow me to see the display when pinpointing (and keep the display off the ground).

I came up with 4" of 1" poplar dowel, two pieces of 5/16" dowel and 1" of 3/16" dowel plus an 11" cable-tie. Minwax walnut stain and shellac, plus I got fancy and put a bolt-boot over each of the dowel feet. Weight: 1/3 ounce. The 3/16" stub fits in an existing shaft length adjustment home and the cable-tie is figure-of-eight wrapped around the shaft and stand. No alterations to the detector.

Today was the first "in-the-field" trial and it worked great.

I came up with 4" of 1" poplar dowel, two pieces of 5/16" dowel and 1" of 3/16" dowel plus an 11" cable-tie. Minwax walnut stain and shellac, plus I got fancy and put a bolt-boot over each of the dowel feet. Weight: 1/3 ounce. The 3/16" stub fits in an existing shaft length adjustment home and the cable-tie is figure-of-eight wrapped around the shaft and stand. No alterations to the detector.

Today was the first "in-the-field" trial and it worked great.

Amazon Forum Fav 👍

Attachments

Upvote

0

You'll notice I even fluted the main body for "lightening" and visual effect.

You'll notice I even fluted the main body for "lightening" and visual effect.