Nugs Bunny

Hero Member

- #1

Thread Owner

It's recommended that the differential pinion shaft lock bolt be replaced whenever it's removed. They cost less than $2.00 and it must be removed to perform any repairs on most differentials.

A routine job such as replacing rear axle seals can turn into a nightmare if a weak lock bolt breaks. I have always replaced this bolt whenever I service a differential, $1.59 seems like pretty cheap insurance to me.

While attempting to replace the rear axle seals on my F-150 the lock bolt broke off, leaving some threads and the pin in the pinion shaft. Judging by the condition of the head of the bolt, it has been reused many times. This is the first time I have worked on the differential on this specific truck.

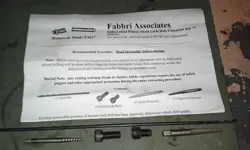

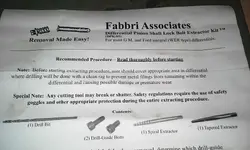

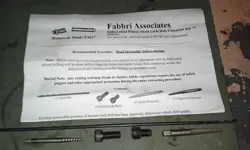

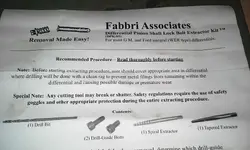

I searched the forums looking for ideas, there is no clearance for a drill and other than cut the pinion shaft or carrier I was out of ideas for the moment. I finally came across an extractor kit for $31.95 that promised a broken lock bolt could be removed in 5 minutes with it.

Well that was a lie... it only took about 3 minutes! I'm pretty stoked right now, it's not often stuff ordered off the internet works better than promised.

If you have faced this problem, or if you think it just sounds like a good tool to have on hand, it's sold by Fabbri Associates FABBRI ASSOCIATES

A routine job such as replacing rear axle seals can turn into a nightmare if a weak lock bolt breaks. I have always replaced this bolt whenever I service a differential, $1.59 seems like pretty cheap insurance to me.

While attempting to replace the rear axle seals on my F-150 the lock bolt broke off, leaving some threads and the pin in the pinion shaft. Judging by the condition of the head of the bolt, it has been reused many times. This is the first time I have worked on the differential on this specific truck.

I searched the forums looking for ideas, there is no clearance for a drill and other than cut the pinion shaft or carrier I was out of ideas for the moment. I finally came across an extractor kit for $31.95 that promised a broken lock bolt could be removed in 5 minutes with it.

Well that was a lie... it only took about 3 minutes! I'm pretty stoked right now, it's not often stuff ordered off the internet works better than promised.

If you have faced this problem, or if you think it just sounds like a good tool to have on hand, it's sold by Fabbri Associates FABBRI ASSOCIATES