Capt Nemo

Bronze Member

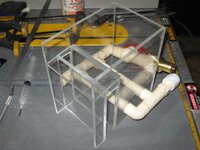

In the mood to build something again. Got an idea to try another recirculating fluid bed concentrator. I'm looking at a deep bed over 4"deep, and about 4x4" in area. I also want to be able to hook it onto the side of a 5 gallon bucket to catch the tailings. Debating whether to use a DC 500 gph pump or an AC 120 gph fountain pump. Also debating about a feed hopper so I can use a scoop instead of a spoon.