I spent some hours today polishing screws and working on cleaning up the balance wheel. I kind of jump around.

There is a half reason for jumping around, I want to get all the parts for the time part of the watch working. Then once it's working and ticking move to the chronograph parts.

I haven't even started polishing all screws, just the ones with rust. I'm not thrilled with my final finish on some. Until I figure out which ones are visible when the watch is together, I'm kind of roughing them in for now. That and this takes Hours and hours to put a mirror shine on all screws. It does for me at least.

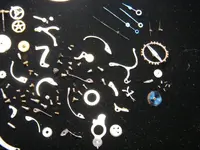

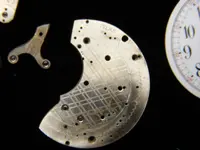

Here's more pics..

The big stone is for really crusty pitted screws, then the smaller stone, then a little Simichrome on a brass block. I started using the lathe at different speeds, usually slow at first, then with the simichrome and brass running it at a higher speed down to barely touching the screw head, almost no pressure at all. I also found that if I took a a piece of paper and held the screw in tweezers with barely any simichrome for a final polish works good too. Each screw from start to finish is anywhere from 10 to 30 min for me. This is why I started short cutting until I know which screws will be seen or not.

The reason I used simichrome is because it was in the bench, I'm sure any fine polish or many other methods work. I'm still learning and this is the way it's working for me so far and until I find a better or faster way! All I know is every once in a while I still hear and feel a piece of the diamond powder hit and put a heavy scratch in something I'm trying to polish! I wish I would have never opened that stuff up!!!

Most looked great in the sun light! Now that I'm working under the bench light only, I see more fine scratches. I'll touch the visible screws up later. I still have a lot more to do yet..

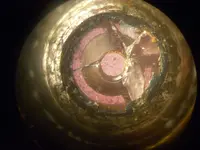

Rusty balance...

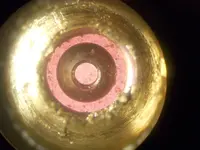

Balance with screws removed...

Balance part way done..I'm still kind of picking at it. I had to leave a few pits, if I sand until those are gone? I think I'll be removing too much material. They are deep pits. I had to remove a lot as it was, the rust was pretty bad. Basically what I'm picking at now is the arm or spoke? I want that a little nicer and matching the look of the other side. I'm hoping the screws/weights will polish up when it goes in the cleaner. Then I'll check it for round and poise. It probably should have been replaced, but my goal is to try to save anything I can and I'm sure I'll be picking at this watch forever! So, for now, I'm going to have to leave some things if I ever want to make it through the project and keep this thread going! If not It will take forever! I'll Just keep finding flaws!

I also just read on the net that Tea will eat out the iron oxide. I guess tea is a little better than using vinegar. Sorry, I was jumping around and don't know what article or who to give the credit to... A net search will bring it up and go into more detail.

This could still end up in a parts pile! You just never know with me! Heck I don't even know what I'll do yet!

This could still end up in a parts pile! You just never know with me! Heck I don't even know what I'll do yet!