sodetraveler

Sr. Member

- #1

Thread Owner

On Sunday night I pulled a couple more bottles from my cliff-side hole

One was an applied lip black glass wine - nuff said about that.....

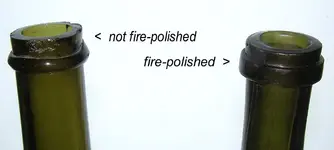

The other was what I at first thought was an ABM screw top whiskey flask. I arrived at this conclusion because when I did a quick check of the top I noted that it was smooth - and in the past any handblown bottle with a screw top had a ground lip (except for some ketchups that have a significant smooth section above the threads).

When I got home and cleaned it off I was presented with a bit of a mystery. There is no seam going through the threaded portion at all, so it's certainly not ABM!

The seam stops at the bottom of a horizontal ring that goes around the neck. The seam also takes a hard bend to the left as it goes up the neck, which suggests that the entire top was twisted while it was still hot (i.e. during lip forming operations).

Now, in the past when I've seen a seam dissapear into the bottom of the lip it almost always indicated an applied lip - especially if there were no horizontal tooling marks. However, this particular lip doesn't have any of the typical "glopped on" appearance of an applied lip

You guys have probably seen more of these than I have. Any idea how this lip was formed and/or applied? I appreciate any suggestions

One was an applied lip black glass wine - nuff said about that.....

The other was what I at first thought was an ABM screw top whiskey flask. I arrived at this conclusion because when I did a quick check of the top I noted that it was smooth - and in the past any handblown bottle with a screw top had a ground lip (except for some ketchups that have a significant smooth section above the threads).

When I got home and cleaned it off I was presented with a bit of a mystery. There is no seam going through the threaded portion at all, so it's certainly not ABM!

The seam stops at the bottom of a horizontal ring that goes around the neck. The seam also takes a hard bend to the left as it goes up the neck, which suggests that the entire top was twisted while it was still hot (i.e. during lip forming operations).

Now, in the past when I've seen a seam dissapear into the bottom of the lip it almost always indicated an applied lip - especially if there were no horizontal tooling marks. However, this particular lip doesn't have any of the typical "glopped on" appearance of an applied lip

You guys have probably seen more of these than I have. Any idea how this lip was formed and/or applied? I appreciate any suggestions