well, as usual....when I have to much time on my hands, I start tinkering with stuff. Today, I decided to get a ball valve for the hopper, but nobody had the connections and adapter I needed.

finally after adding the valve and rotating the inlet / valve assemble outward and away from the hopper, I noticed a problem.... I could only rotate 180º. If I wanted to angle the inlet "down" it interferred with the plastic "lip" of the hopper, causting it to bulge and bow outward.

pic of the hopper and valve attached roated in travel position:

pic of the area where the pipe interferes with the hopper lip:

I figured in order to get a downward angle I could either attach a PVC elbow or cut a notch in the lip of the hopper. I figured what the heck.....

I marked the area that needed to be cut out:

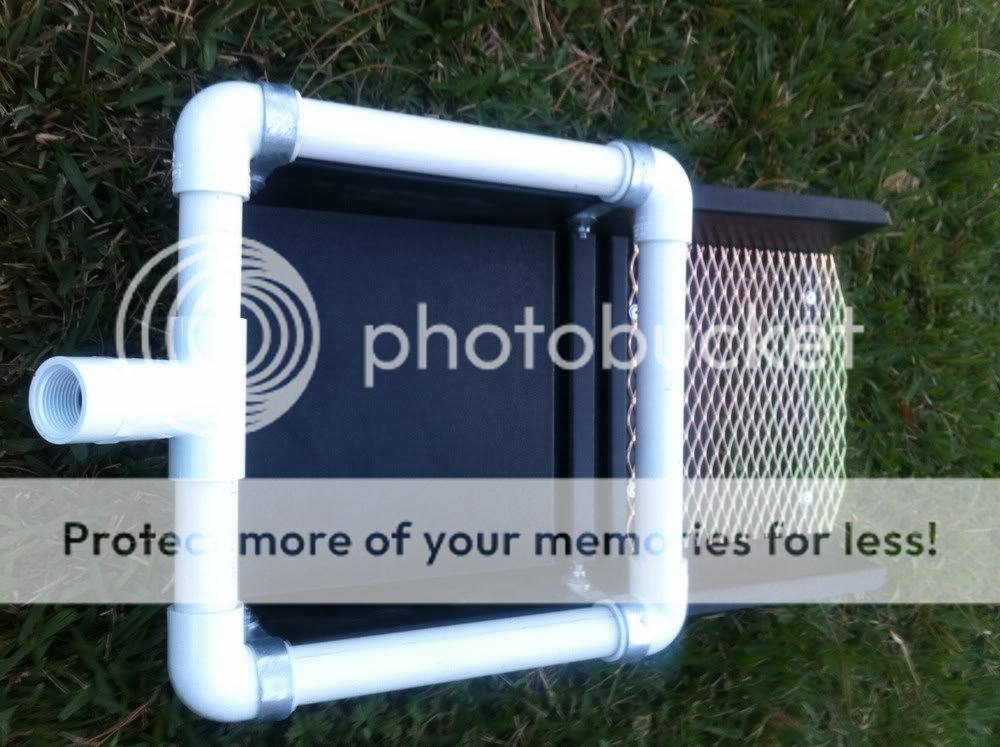

Here's a shot of the underside of the spraybar assembly after taking it off the hopper:

after the cut out..... much better. I can now angle the whole thing down w/ no probs...the pipe clears the lip....

lastly, I decided to build a full 1 inch reducer that would handle serious pressure. The hopper inlet is 1", and the pump will be bringing in a 2" hose. I wanted to build the strongest bottleneck adapter to the hopper that I could. I encorporated a steel 1" threaded nipple adapter to a 2" male outlet (PVC), and cemented the sucker from the inside along the threads. Then I added a female in / out coupling, and cemented that as well. This 2" to 1" custom bottleneck adapter is a beast. I figure I'd give some run flat hose an aneurysm before this adapter fails.

someone with more experience with pumps, and how they lose power based on distance please chime in

someone with more experience with pumps, and how they lose power based on distance please chime in  I can get a more powerful pump, but the next step up is more that 2x the power I need in water movement, and the in/out is 2 inches.....that would mean the hopper opening would be a huge bottleneck and put unnecessary strain on the pump, right?

I can get a more powerful pump, but the next step up is more that 2x the power I need in water movement, and the in/out is 2 inches.....that would mean the hopper opening would be a huge bottleneck and put unnecessary strain on the pump, right?