hvacker

Bronze Member

- Joined

- Aug 18, 2012

- Messages

- 2,357

- Reaction score

- 1,906

- Golden Thread

- 0

- Location

- New Mexico USA

- Detector(s) used

- My Head

- Primary Interest:

- Other

Ok... here is my dealio with SS...

Let me paint a picture for yas...

1.2 million dollar boat...

Fiberglass / gel coat...

Has teak bow rail from stern to bow...

Rail done with regular steel wool...

Guy shows up next morning to see his 1.2 million dollar boat COVERED with 1.2 million RUST dots... little squigs and lines.

Overnight... in salt and morn dew.

Guess what...

Now your are either scrubbing for days trying to remove every rust spot... your fired... and you might be paying thousands in time and gelcoat.

So...

See the light ?

I'm scratching my head to remember. Was it teak in particular that had a reaction to regular steel wool or was it more general.

I know teak absorbs silicon from the soil. Probably part of a process like petrifaction happened in the turning wood into stone.

Teak can be tougher on power tools because of silicon. The guy on the show Yankee Workshop turned me on to the silicon attribute

teak has when he built a teak bench.

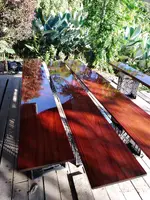

Rust can be used to stain wood. Soak a wool pad in some water and you will get a rather nice color if your heading toward a cherry

look. I believe steel wool leaves stuff behind in the wood grain. I've seen it when I've done a wipe down. But at least with teak I would be careful using regular steel wool.

AARC is the gel cote you use a poly product? I've only used Gel once. I have seen it used for projects on woodworking shows and they seem to like the way it works.