No I have not tested it yet, but i've been thinking about making myself a dredge so been looking around for the different sizes needed but thought a calculator could be nice to have.

But i asked ChatGpt to help answer some questions as I'm not an engineer and now i understand

"

The feedback you received brings up an important aspect of engineering design, especially when it involves fluid dynamics: theoretical calculations must ultimately be tested and validated against real-world conditions, which can include a variety of factors not accounted for in simplified models.

Bernoulli's principle and the continuity equation give us a theoretical basis for calculating flow rates and pressures in an ideal scenario. However, in practice, there are additional factors such as turbulence, friction losses inside hoses and fittings, and the interaction of the water jet with the material being dredged, all of which can affect the performance of the system.

Regarding the feedback:

- Jet Diameter and Water Movement: Reducing the jet diameter while keeping the pressure constant will increase the velocity of the water at the point of constriction (the jet). According to Bernoulli's principle, this should increase the suction power because the higher velocity at the jet results in lower pressure, enhancing the vacuum effect. However, there's a trade-off: a smaller jet reduces the volume of water that can pass through per unit of time, which could result in moving less material overall.

- Creating a Vacuum: The creation of a vacuum for suction is more about the velocity of the water than the volume. A high-velocity jet will create a stronger vacuum, but there needs to be enough water volume to carry the material away.

- Real-World Testing: The person who provided feedback likely encountered a scenario where the balance between jet size, water velocity, and volume did not match the demands of their specific dredging conditions. Real-world testing often reveals the need for adjustments from theoretical models. What works on paper might not work in a riverbed with variable material densities and compositions.

In summary, both the volume of water and the velocity (related to pressure) at which it moves are crucial. A smaller jet can create a higher velocity and potentially a stronger vacuum, but there must be enough water to carry the material. Conversely, a larger jet allows more water flow but at a potentially lower velocity, which could reduce suction.

Finding the optimal balance often requires field testing and adjustments based on performance. The goal is to find a jet size that offers the best combination of water velocity and volume to create sufficient suction and material transport for your specific dredging conditions.

You

but how can the velocity of the water increase with a smaller jet, if the pressure is the same? I'm not an engineer so i don't understand how that could work. The pressure of the water is the same and in my mind pressure is the same as the speed, just by making it smaller it would just mean less water going into the suction nozzle?

ChatGPT

Your confusion is completely understandable. Let's clarify how pressure, velocity, and jet size interact according to fluid dynamics principles.

Pressure is a measure of force exerted over an area and doesn't directly equate to speed. It's more akin to potential energy in the system. When we talk about the speed or velocity of water in this context, we're referring to how fast the water is moving, which is related to the kinetic energy of the system.

When you have a given pressure at the pump, and you reduce the size of the jet (orifice), you're forcing the same amount of energy (pressure) through a smaller area. According to Bernoulli's principle, when the same amount of water is forced through a smaller opening, it must speed up (increase in velocity) because the energy in the system is conserved. This is similar to putting your thumb over the end of a garden hose; the water sprays out faster and further, even though the pressure from the tap hasn't changed.

Here's the principle at play:

- Larger Jet Diameter: More water can flow through, but the velocity may be lower because the water has more area to pass through.

- Smaller Jet Diameter: Less water can flow through, but it does so at a higher velocity because the same pressure acts on a smaller area.

The increased velocity through the smaller jet creates a lower pressure area (due to the Venturi effect), which contributes to the vacuum effect that sucks material up the dredge's suction hose. However, if the jet is too small, you could indeed end up with insufficient water flow to carry the dredged material, which might be what the person giving you feedback experienced.

The ideal jet size creates a balance where the velocity is high enough to generate good suction but not so high that it reduces the overall volume of water and material that can be moved. It's this balance that's crucial in dredge design, and it's why real-world testing is essential to find the best setup for your particular conditions."

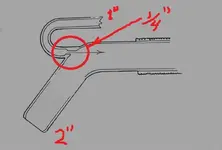

I got the Super Hog

I got the Super Hog