Zaroc

Jr. Member

Hello All,

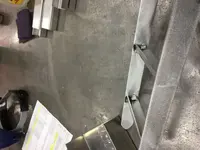

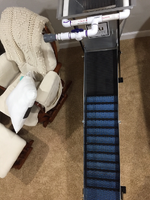

I've been building a new Highbanker this summer, and I ready for testing (I got a little carried away and built a cleanup sluice too)!!! I was wondering if you can point me in the right direction? I want to find a decent volume of paydirt to process in the machine to test its performance. I live in an area where there may be a small amount of flour gold, but I want to be sure this beast is catching EVERYTHING! I don't usually order dirt online, so I'm not sure who is the most reliable. Is there a trusted company to order from? How much would you suggest to break this thing in? Are there specific test I should perform besides just turning the water on? And other than just running dirt, do you recommend I do anything else to test it or "season" it before our first adventure into the unknown?

I appreciate your feedback!

Z

I've been building a new Highbanker this summer, and I ready for testing (I got a little carried away and built a cleanup sluice too)!!! I was wondering if you can point me in the right direction? I want to find a decent volume of paydirt to process in the machine to test its performance. I live in an area where there may be a small amount of flour gold, but I want to be sure this beast is catching EVERYTHING! I don't usually order dirt online, so I'm not sure who is the most reliable. Is there a trusted company to order from? How much would you suggest to break this thing in? Are there specific test I should perform besides just turning the water on? And other than just running dirt, do you recommend I do anything else to test it or "season" it before our first adventure into the unknown?

I appreciate your feedback!

Z

Upvote

0