This is what I learned yesterday at the GPAA gold show. Sluices are not made right!

They are best at placer gold recovery, but share a common design flaw that reduces maximum gold recovery.

The purpose of a sluice is to separate all sizes of gold from the other material such as gravel, sand, dirt, etc. trapping the gold and eliminating the waste.

To achieve that task a sluice needs to:

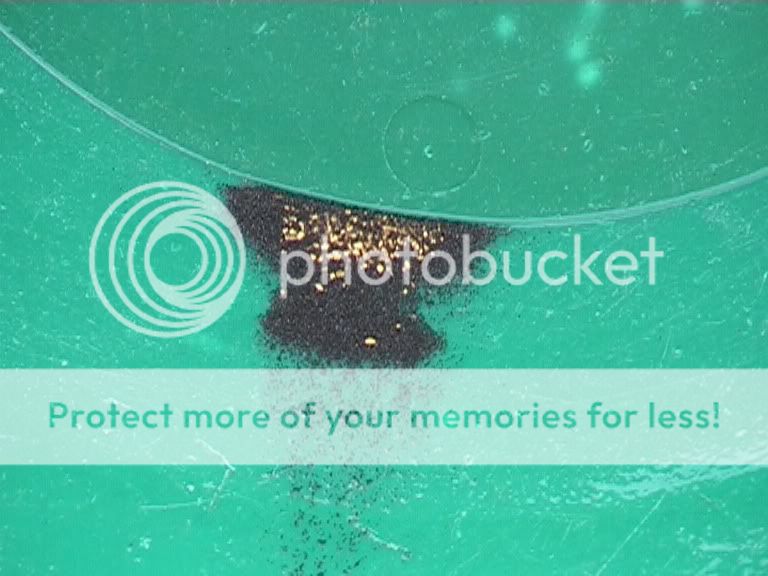

Create the proper vortices to allow the different sizes of gold to separate and drop out of the water flow to then become trapped for recovery.

Here is the main design flaw in sluices:

The water flow over the riffles is going the same speed as the water flow over the expanded mesh. Because the expanded mesh is located in the same part of the sluice as the riffles there is no way to adjust the water speed separately. * see below.

Expanded mesh is best at trapping small or fine gold. But for the proper vortex to form, the water speed needs to be a lot slower than for riffles.

Riffles are best at trapping larger gold but to form the proper vortex the water speed needs to be a lot faster than for expanded mesh.

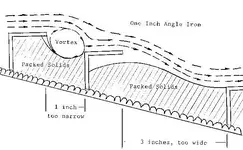

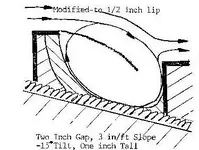

Riffle height should be no more than 1" tall and then the top lip not extend forward more than 1/2 inch and the 1/2 inch lip should be elevated 15 degrees above perpendicular to the sluice box and the riffles should then be only 2 inches apart. any more or any less apart will not create the optimum vortex.

Here is a link where this info may be verified :

http://ygsftp.gov.yk.ca/publications//tech/placerrecovery.pdf

Go for the gold!

GG~

*

To overcome this problem, a proper sluice design would have to have a way for reducing the water speed over the expanded mesh while allowing faster water speed over the riffles. But how do you achieve that and still be able to keep the sluice clear from building up too much material at the slow part?

Can a sluice be designed to eliminate that problem?

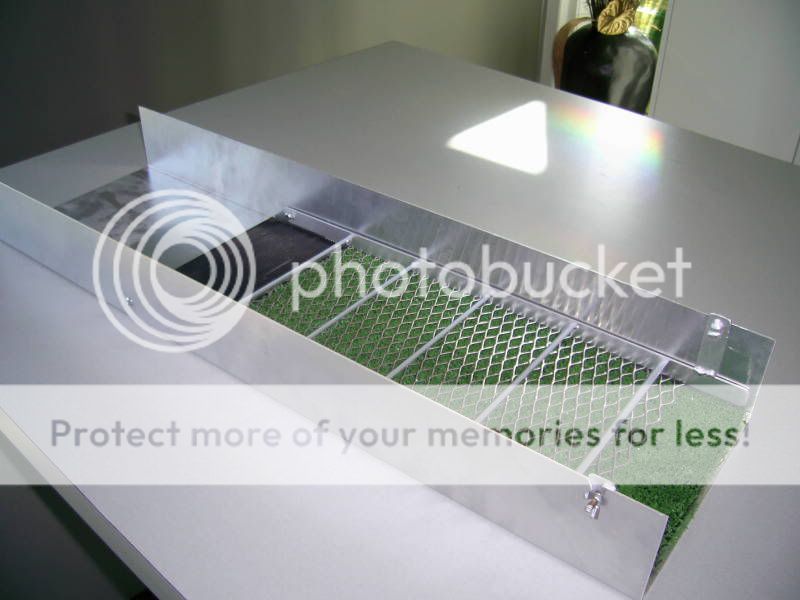

). I was assuming I needed to remove the expanded metal from my A-52 highbanker/2.5" dredge conversion now that I was finally getting around to putting in the dredge/highbanker riffles. I've used it for years with the original (only a few times a year) so I guess it's about time. Lowered the angle of the grizzly so it doesn't shed material quite as fast. I also put a plate in the hopper that directs the slurry to the very top of the sluice rather than dumping it straight down. Punch plate for the 1st foot of the sluice, then about 8" of nothing(but carpet), then the riffles. Ribbed carpet from one end to the other. Need to put in a light rubber flap near the top to smothe the flow a bit.

). I was assuming I needed to remove the expanded metal from my A-52 highbanker/2.5" dredge conversion now that I was finally getting around to putting in the dredge/highbanker riffles. I've used it for years with the original (only a few times a year) so I guess it's about time. Lowered the angle of the grizzly so it doesn't shed material quite as fast. I also put a plate in the hopper that directs the slurry to the very top of the sluice rather than dumping it straight down. Punch plate for the 1st foot of the sluice, then about 8" of nothing(but carpet), then the riffles. Ribbed carpet from one end to the other. Need to put in a light rubber flap near the top to smothe the flow a bit.