Jeff95531

Silver Member

- Joined

- Feb 10, 2013

- Messages

- 2,625

- Reaction score

- 4,094

- Golden Thread

- 0

- Detector(s) used

- Teknetics Alpha 2000

- Primary Interest:

- Prospecting

It rained all last week. It rained all this week. Forecast for next week? You guessed it. So I dug out the Miller Table, took notes on what was wrong/needs to be fixed and there it sat. In the mean time, I gathered my super fines from the last trip to dial in the table once I get around to it. Then, my good buddy Delnorter PM's me with an offer of not only a few pounds of gold bearing black sands to feed my table, he also had concentrates from a recent gold/platinum and silver producing solo prospecting spot he discovered. Was I interested? Oh yeah!

Mike brought everything over and as he pulled out baggies of dart black sand, he also shows me the coolest plastic mini classifier set I've ever seen. He also lends me his black sand magnet/plunger which is something else I must have. As the new list of must haves roll in the background, he offers up this latest spot of his is accessible even now as flooding surrounds meaning it just may be an old river channel with good to moderate access. OK, now I'm excited...

But, first things first. The table taught me a lot since I got it, especially what not to do. One big problem is I never got full side to side coverage/discharge. I also let the pump sit in fines which reduced it to next to nothing for flow, even with attempts to revive it. So, I replaced the pump, put it in the filter/container and discovered the discharge hose was way way longer than it needed to be so cut it in half. Also used a different/courser scratch pad along with the denser stuff it came with.

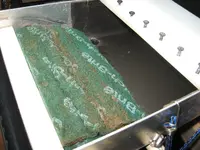

I finally got it to be full and flat board (as a baseline) not to mention his black sands are freakin heavy! After lots of tweaking yesterday and today on the table, it's about right. I still have to reduce the amount of spray bar diffuser material I added in the head cuz max flow is not just not there yet. So far I'm finding 8% to 10 % loss in the discharge pan so not bad for not done.

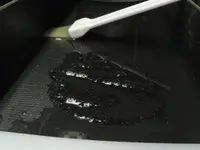

The water diffusing pads where packed with fines as shown in the pics. I took advantage of the rain to flush out "the mats".

The water diffusing pads where packed with fines as shown in the pics. I took advantage of the rain to flush out "the mats".

There may be some extra pics...can't confirm deletes.

Mike brought everything over and as he pulled out baggies of dart black sand, he also shows me the coolest plastic mini classifier set I've ever seen. He also lends me his black sand magnet/plunger which is something else I must have. As the new list of must haves roll in the background, he offers up this latest spot of his is accessible even now as flooding surrounds meaning it just may be an old river channel with good to moderate access. OK, now I'm excited...

But, first things first. The table taught me a lot since I got it, especially what not to do. One big problem is I never got full side to side coverage/discharge. I also let the pump sit in fines which reduced it to next to nothing for flow, even with attempts to revive it. So, I replaced the pump, put it in the filter/container and discovered the discharge hose was way way longer than it needed to be so cut it in half. Also used a different/courser scratch pad along with the denser stuff it came with.

I finally got it to be full and flat board (as a baseline) not to mention his black sands are freakin heavy! After lots of tweaking yesterday and today on the table, it's about right. I still have to reduce the amount of spray bar diffuser material I added in the head cuz max flow is not just not there yet. So far I'm finding 8% to 10 % loss in the discharge pan so not bad for not done.

The water diffusing pads where packed with fines as shown in the pics. I took advantage of the rain to flush out "the mats".

The water diffusing pads where packed with fines as shown in the pics. I took advantage of the rain to flush out "the mats".

There may be some extra pics...can't confirm deletes.

Amazon Forum Fav 👍

Attachments

-

014.webp106.4 KB · Views: 149

014.webp106.4 KB · Views: 149 -

018.webp729.4 KB · Views: 153

018.webp729.4 KB · Views: 153 -

020.webp638.5 KB · Views: 146

020.webp638.5 KB · Views: 146 -

022.webp544.5 KB · Views: 141

022.webp544.5 KB · Views: 141 -

024.webp163.7 KB · Views: 142

024.webp163.7 KB · Views: 142 -

025.webp115.7 KB · Views: 143

025.webp115.7 KB · Views: 143 -

027.webp432.2 KB · Views: 150

027.webp432.2 KB · Views: 150 -

029.webp141 KB · Views: 145

029.webp141 KB · Views: 145 -

032.webp643.9 KB · Views: 145

032.webp643.9 KB · Views: 145 -

033.webp619.5 KB · Views: 161

033.webp619.5 KB · Views: 161 -

034.webp614.2 KB · Views: 152

034.webp614.2 KB · Views: 152

Last edited:

Upvote

0

)

)  What a difference!

What a difference! Well of course I accidentally dumped it all into the main tub during testing...so must start over. Is there any other way?

Well of course I accidentally dumped it all into the main tub during testing...so must start over. Is there any other way?