SaltwaterServr

Sr. Member

- #1

Thread Owner

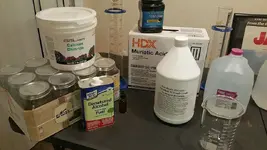

I finally got my 35% hydrogen peroxide in today so I'm pretty much ready to go. I'll be working to figure out the oxidation time using 7% H2O2, then chlorinate with 2M HCl with 20grams per liter of NaCl added. The chlorination will take about 48 hours. Then to introduce the carbon, let it sit for a bit. Once the gold is adsorbed to it, wash then incinerate. Smelt the ashes, see what she's got in her.

The photo below shows two different ores we're working with, both sulfide refractory ores. The red on the left we call "death" ore because the arsenopyrite almost killed my mining partner. The batch on the right is from our Green Mine. The death ore has good arsenopyrite in it, but you have to put a loupe to it to see it. The Green Mine ore, well, you can see that glitter on the washed piece in the container; it's got amazing amounts of arsenopyrite in it.

I'm sending both off for assay pretty dang soon.