In the gold-rush jungle hinterlands of the island of Mindanao, Philippines the typical artisanal miner has to make do with whatever tools he has and oftentimes resort to improvisation. I presume this is quite true in Africa as well as in South America.

For example, if the banned toxic amalgamating agent mercury is not available the ore (has to be high-grade) after being ground to the desired fineness using an improvised rod mill (takes around 8 hours for a 40-kg bag) is carefully panned to get the desired concentrate which could be a mix of gold particles, sulfides and other heavier materials.

Again, in the absence of mercury, the concentrate is "cooked" in a stainless steel bowl (readily available and particularly unaffected by nitric acid) on a wood fire and using nitric acid (the dilution dependent upon the "cook" or miner). One learns not to stay in the downwind as the nasty, corrosive brownish red NOx fumes billows in the breeze. When the concentrate is "cooked", i.e,. no more fumes, it is carefully washed with water from a nearby stream and gently panned. The lighter materials including the sulfur (like regurgitated infant milk) are removed with further washing.

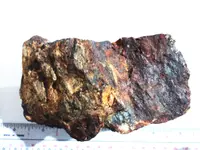

The remainder is an agggregate of fine to coarse gold and other acid-resistant constituents like magnetite. The gold may not look the typical gold-- it could be off-colored like reddish dirty with some black "varnish" but nevertheless gold with its typical high specific gravity. Placed on a clay dish with a little borax and "cooked" again using a reducing flame from a DIY gasoline torch, the golden particles melt and coalesce and lose their dirty "overcoat".

The size of the final yield (still unrefined) ranges from a centavo (penny) to a small medallion (if you're lucky). Big or small they all look pretty. Gold!

tabu