- Joined

- Nov 14, 2010

- Messages

- 4,958

- Reaction score

- 14,522

- Golden Thread

- 0

- Location

- The Great Southwest

- Primary Interest:

- Prospecting

In the Calling all "clay" hater's!! thread I managed to share some useful information about how to break down clay by raising the pH with some simple cheap chemicals that are environmentally friendly.

Now that you've gotten the gold out of the clay you are left with some seriously muddy water. Recycling that water can only take place after you turn it from chocolate milk back to clean clear water. You could use large bodies of water and long settling times if you have the room, water and time. You could try to depend entirely on the flocculation process and just reverse the pH change we made to break down the clay. That involves mixing in a bunch of acid and voila your muddy water turns back into clay again.

The problem with using that acid flocculant system is you are left with clay and acid water - bad idea if you are going to recirculate the water because your chemical use goes way up when you try to breakdown the next load of gold holding clay. This creates a cycle that ends up with a toxic soup and wasted chemicals. The addition of acid also leaves us with water we can't recycle back into the environment. The same clay ground (low pH) that neutralized our high pH clay busting chemicals can't neutralize the acid water left from the acid flocculation process. You are left with more clay and acid pH water that is essentially useless for recirculation or further processing and a real environmental problem if you dump it.

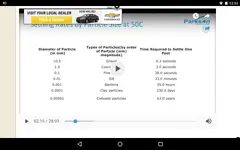

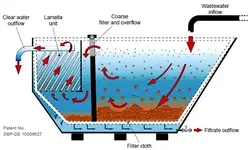

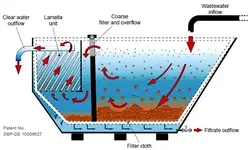

Lucky for us there is a quicker, easier mechanical way to remove the mud from the water - the Lamella Separator. Although the principle of the lamella separator isn't new it's only been used for mining since the mid 1970's. The lamella separator requires no motors or electricity so once your system is tuned for your conditions you have no costs for operation and very little maintenance. Here's a little diagram to show the principle of operation.

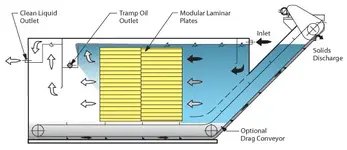

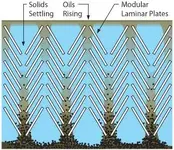

Yeah it's that simple. The muddy water flows into one end of the tank and the clean water flows out the other end. The secret is those slanted plates on the outflow side. Everything else is pretty much like your average settling tank but the slanted plates cause the solids to drop out before the water can reach the outflow. Here's a little video to show you a working model and demonstrate the simple principles involved.

You will see these lamella separators at any major mine using water processing. They are pretty easy to spot because they are usually lopsided to accommodate the slanted plates. They can be big or small.

Here's one for a big mining operation.

And here's a small one easily transported and setup on a small operation.

You can even buy or make your own plates for a homegrown water cleaner system. These are bulk made pre - cut plastic lamella tubes.

Heavy Pans

Now that you've gotten the gold out of the clay you are left with some seriously muddy water. Recycling that water can only take place after you turn it from chocolate milk back to clean clear water. You could use large bodies of water and long settling times if you have the room, water and time. You could try to depend entirely on the flocculation process and just reverse the pH change we made to break down the clay. That involves mixing in a bunch of acid and voila your muddy water turns back into clay again.

The problem with using that acid flocculant system is you are left with clay and acid water - bad idea if you are going to recirculate the water because your chemical use goes way up when you try to breakdown the next load of gold holding clay. This creates a cycle that ends up with a toxic soup and wasted chemicals. The addition of acid also leaves us with water we can't recycle back into the environment. The same clay ground (low pH) that neutralized our high pH clay busting chemicals can't neutralize the acid water left from the acid flocculation process. You are left with more clay and acid pH water that is essentially useless for recirculation or further processing and a real environmental problem if you dump it.

Lucky for us there is a quicker, easier mechanical way to remove the mud from the water - the Lamella Separator. Although the principle of the lamella separator isn't new it's only been used for mining since the mid 1970's. The lamella separator requires no motors or electricity so once your system is tuned for your conditions you have no costs for operation and very little maintenance. Here's a little diagram to show the principle of operation.

Yeah it's that simple. The muddy water flows into one end of the tank and the clean water flows out the other end. The secret is those slanted plates on the outflow side. Everything else is pretty much like your average settling tank but the slanted plates cause the solids to drop out before the water can reach the outflow. Here's a little video to show you a working model and demonstrate the simple principles involved.

You will see these lamella separators at any major mine using water processing. They are pretty easy to spot because they are usually lopsided to accommodate the slanted plates. They can be big or small.

Here's one for a big mining operation.

And here's a small one easily transported and setup on a small operation.

You can even buy or make your own plates for a homegrown water cleaner system. These are bulk made pre - cut plastic lamella tubes.

Heavy Pans

Upvote

0