joebwhit

Jr. Member

- #1

Thread Owner

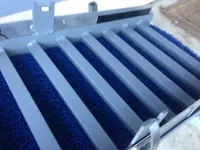

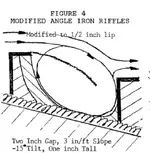

So I got a wild hair and weled up some new riffles. I based everything off the clarkston research. I used 3/4"x3/4" angle iron and 1 1/2" flat bar. at 3/4" tall they should have been spaced 1 1/2" apart from down stream edge to up stream edge with a 15 degree pitch to them. I am running it with a 2" pump at about 120gpm. I know these riffles can handle more water but this should have been close to enough. the material piled up behind the riffles. when poking at with my finger you can tell there is a lot of force holing it down, but a full circle vortex was not forming. I think but am not sure, that due to the riffle being pushed down fairly hard into my moss that the actual height of the riffles was closer to 1/2" or 5/8" at best. that being said my spacing should have been closer 1" - 1 1/4". what do you think? thoughts, advice? dont' judge my welds. that was nearly my first time stick welding something this small.

?

?