- #1

Thread Owner

All that gargin got me lost, my supply line needs a reducer before entering my nozzle? Is that correct

One thing im having trouble wrapping my mind around is the one hose design, unless ur using a fairly large pump i cant see how it would work also u would need a short suction hose if ur not using a large enough pump. Ive figured out my flaw in my design and working on fixing it but wanted more insight on the single hose design before i modify or redesign my nozzle thanks for the insight

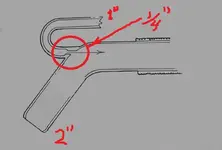

I know very little. However you may be able to go online and see that the 90 degree angle may not be the best angle. Also the input pipe may need to be changed. Just my 2 cents input here. There are others that know a lot more about this.View attachment 1943026View attachment 1943026

Hello !

For some reason my nozzle does not work well.

Any suggestions? recommendations?