TintedSnow

Full Member

- Joined

- Sep 25, 2016

- Messages

- 143

- Reaction score

- 147

- Golden Thread

- 0

- Location

- Anchorage, Alaska

- Detector(s) used

- Equinox 800, White's Goldmaster

- Primary Interest:

- All Treasure Hunting

- #1

Thread Owner

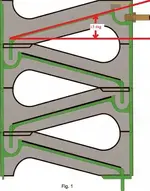

I don't exactly have the $500 bucks to shell out on a new Gold Cube, but I realllllly want one. So I've started off on an adventure to build my own! My family owns a car shop, so I have access to all the tools I need. I drew up some plans today. Anyone ever built their own? Or anything similar? I'll upload pics when I start the build.