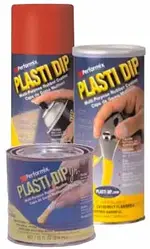

Here are pictures from a headset mod I did on one of my Excals... The same mod would work for you on your cable....The Plasti-dip is the secret....It is a rubber coating, it has worked great on the cable mods on my excals

I would cut the bad insulation off, cover the cable with liquid tape and let it dry. I would then cut two pieces of heat shrink one about 1.5 inches longer than the other slide the short one on the cable first followed by the second one, insert something to use as a strength member at the bad point, I have used a piece of tiewrap and insulation off a heavy gage extension cord, but anything nonmetallic that is stiff would work.

You covered the bad spot with heat shrink tubing heat it and seal it with liquid tape, when it dries slide the 2nd heat shrink over the repair so that the first piece is in the center of the second longer piece, heat it then cover it with liquid tape, then spray it with plasti-dip, I would put on at least 4-5 coats. I would tiewrap the cable to the shaft so it cant pull on the connection...I would make sure the heat shrink is long enough that the heat shring coveres at least half the connection plug on the coil...

Use the Plasti-Dip to ensure it is waterproofed.…… I have done 3 mods so far and none have leaked yet and they have been in the water a lot....

I Covered The Splice With Insulation Cut Off An Old Piece of Extension Cable, Then Added 2 Layers Of Heat Shrink With Strength Members Between the 2 Layers

Splice After The Final Coat Of Plasti-Dip......(Total Of 5 Spray On Coats)