Thought I would share some additional info that I have learned from trial and error.

I have found that the number and diameter of the fluidizing tubes as well as the holes along with their orientation need to be "tuned" to the size of the trap to create optimum fluidization.

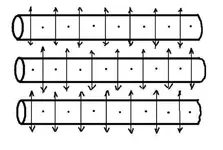

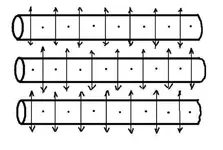

One proven hole pattern is to have holes across the bottom of each tube as well as out the sides of each tube.

Here is an example of a staggered hole pattern that I use with success.......

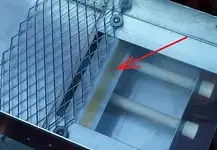

I would recommend that you NOT install the tubes more than 1/2 inch from the bottom of a tube to the bottom of the trap.

And you also should not allow more than 1 inch above the tubes to the lip of the overflow port of the trap. The reason why is: The more material that collects above the center line holes in the fluid tubes the harder it is to keep the trap fluidized.

For example:

Allowing 1/2" below the tubes and then 3/4" for the tubes and 1" above the tubes would set the trap depth up to the bottom lip of the discharge port at 2-1/4". A larger deeper trap doesn't translate to more gold, only more material to try and keep fluidized plus more concentrates to process. The most important thing is to keep the material in the trap fluidized so that the gold can settle through it. Make sense?

Much easier to do when the mass of the material in the trap is reduced.

In other words, the water pressure created inside the tubes must be greater than the pressure created from the weight of the material in the trap for the contents of the trap to become/remain fluidized.

The holes on the sides of the tubes should not be spaced more than 1" apart and should be aimed at the gap between the holes on the tube next to it amounting to a jet of water into the material between the tubes every 1/2" same with the holes on the bottom of each tube 1 inch apart but with the holes on the tube next to it filling the gap. (not sure this description paints the right picture) It works out if you start the holes 1/2" closer to front of the trap on every other tube.

The distance between tubes should not exceed 2" and from the outside tubes to the walls of the trap should not exceed 1"

As far as the proper diameter of the holes in the tubes to create the outflow jets that actually do the fluidizing is where it gets complicated.

If the holes are too large exit pressure goes down but if the holes are too small then too much back pressure is created if the incoming flow into the tubes is not great enough. Do you see the catch 22? Also too many holes will reduce the outflow pressure just as too few will not create an even fluidization.

A happy medium must be found as there is no way to precisely control the incoming flow into the tubes other than using a water pump with an adjustable flow control valve.

Long story short I've found that typically anything over 1/8" holes is too big and anything below 1/16" holes is too small.

One thing not discussed in the above info was the best diameter of fluidizing tubes to use.

I use tubes that have a 5/8" inside diameter and determine how many to use by the overall width of the trap.

When using other sizes bear in mind the diameter used will have some affect on the internal pressure so drill your holes accordingly.

* I forgot to address trap length. You want your trap to be long enough from point of entry to overflow port to give the gold it's best chance to settle out of suspension. I recommend at least 8" of length. My first trap was 8" wide by 6" long and it worked ok but I think a little longer would have been better.

(at least that's what she said)

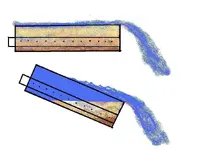

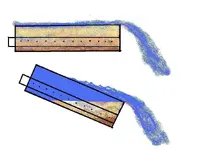

Also run your sluice as level as possible. The steeper the angle the less efficient your trap will be. See diagram below

The bottom angle (45 degrees) is way too steep and will cost you some gold. Shallower angles up to 25 degrees are more acceptable.

Hope this helps,

GG~