I'm using a 4" jet, It's not oversized or anything. My flare is slotted on the log side 4 times to allow clamping. I have about 3" of total lift to the back of my sluice empty of cons, running just water and about 2 3/4" after running for a hour. I'm running a Subaru EX17 6HP engine with a Proline HP350 pump.

This whole year of running I was having issues of jet plug ups, matter fact one after another none stop. While looking at my log, I noticed the side opposite the jet was really beat up from rocks being blasted into the side when hitting the stream of water. I even made my nozzle restrictor smaller, 3.5" vrs 3.75 but that really is not the problem. It's the rocks that are longer on one side then the other. I'm assuming when hit by the blast of water then were being jammed sideways. Any way, on my end the temp solution was to increase my rpms to 3340 to 3400 from 2280. I despise Band-Aid fixes.

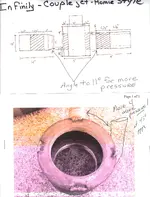

With that all being said, I really see the potential in your jet design. The most obvious being the force of water being directed to the middle, thus eliminating rocks being blasted sideways. Increased suction while using less throttle being another.

One question does come to mind though. If the output tube is smaller and the suction is increased, is this not caused by the venturi effect? I'm trying to remember my Fluid Dynamics class from years ago, so please forgive me if I get this wrong. With this increase in suction, (pressure differential) your having a increase in velocity but a decrease in volume. Once again, please forgive me if I get this wrong as I'm trying to remember a crash course I had years ago in fluid dynamics.

found some info for ya-John

found some info for ya-John

I really think your on to something good here.

I really think your on to something good here.