Hey Jayrock:

I was trying to get back with a quick response, but work has interfered again. You've got the right attitude about learning and this is a good place to add to your education. My “full details” come from a large reference library, a lot of work in the lab and several years of mining projects in a country that specializes in silver exploitation. But, this will be more like a “Cliff Notes” version on silver ore treatments.

Most silver mined today are from sulfide ores such as argentite (acanthite) and pretreatment to remove the sulfides will include; roasting, chemical and aerobic bacteria leaching. Each method has it's pros and cons, but they are all are economically viable for commercial applications.

Roasting (oxidizing) is fast, but has higher start up costs for equipment and environmental concerns. Bacteria is cheap and can be done in any batch/vat/heap leach, but may require a finer grind size, has a slower reaction time and is effected by temperature. Chemical treatment is often done the same way using sulfuric acid to recover base metals, even producing more sulfuric acid. It's not as slow as bacteria, but may require a pH change to leach the precious metals.

Unlike HCl and sulfuric (which are considered reducing acids), nitric acid is an oxidizer and not normally used on a commercial leach level as it's to expensive, easily neutralized by carbonates and produces some toxic byproducts, but it's great for analytical testing. The most aggressive nitric acid formula for leaching silver is 1:1 (acid to water), no heat needed for ore testing. Scrap metal testing and extraction is another story.

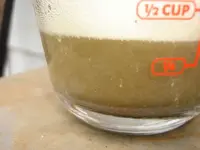

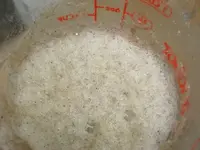

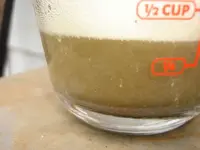

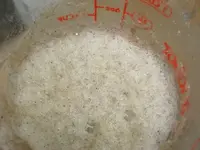

Your top photos look more like effervescence (frothy bubbles) caused by the nitric acid being neutralized by some form of alkali/carbonate material in the ore. The milky white precipitant you are looking for will be in the leach liquid, not on top. Here is an animated GIF link to show you what it should look like;

http://www.chem.uiuc.edu/clcwebsite/AgCl.gif

A thin white milky precipitate indicates the possible presence of silver (or lead, mercury, etc), but probably not in an economical amount. What you're really looking for is a large volume of curdled cottage cheese precipitant.

Here's the nitric acid extraction process;

After ore pretreatment to eliminate sulfides and other gangue material, place a 2 lbs sample in a large glass or plastic container. Cover the sample with about 1 pint of deionized water. Slowly pour in about one-half pint of nitric acid, stir and allow any violent reaction to settle for about 15 minutes. When reaction stops, slowly pour in another one-half pint of nitric acid (equals the 1:1 ratio). Stir occasionally and let set for a couple of hours at room temperature. Everything that's soluble in nitric acid will now be in solution.

After settling, decant off the liquid and filter the pulp with 1 volume of water, then discard the pulp. Now you are ready to chlorinate the liquid. This can be done by slowly adding HCl acid or directly with deionized salt. You're looking for that high value cottage cheese at this point. Also, the color of your filtered liquid might give you a better idea of some of the other contaminates in the ore.

For example; if murky, antimony and/or bismuth are present and precipitating. Violet to purple is manganese. Yellow or orange is iron. Blue or green is copper, and swamp-water gray or black is a combination of all the above.

That's enough info for now. Let us know the results of your pretreatment and nitric leach when you can. If you have the good cottage cheese stuff, I'll post an easy and simple method to convert the chlorides to metallic silver.

Good luck,

John

Thanks, Jay

Thanks, Jay