IMAUDIGGER

Silver Member

- Joined

- Mar 16, 2016

- Messages

- 3,398

- Reaction score

- 5,195

- Golden Thread

- 0

- Primary Interest:

- All Treasure Hunting

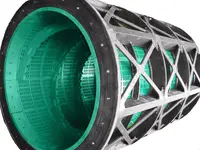

In a situation where the oversized rocks are being cleaned sufficiently, but the fines need further washed (think dirty clay material) does a separate smaller reverse spiral drum for the fines have any advantage over just using a longer scrubber drum?

You don't see the separate reverse spiral drum used very often..so I'm wondering if it has its place or not. Obviously it's more moving parts but less wear and tear on the scrubber drum.

I'm kind of thinking if the heavier clay isn't broke up well enough in the main scrubber, it will just have the tendency to ball up in the spiral.

I'm not talking about a micro trommel (no shovel or 5 gal buckets involved).

You don't see the separate reverse spiral drum used very often..so I'm wondering if it has its place or not. Obviously it's more moving parts but less wear and tear on the scrubber drum.

I'm kind of thinking if the heavier clay isn't broke up well enough in the main scrubber, it will just have the tendency to ball up in the spiral.

I'm not talking about a micro trommel (no shovel or 5 gal buckets involved).

Last edited:

Upvote

0