Hi GoldMine21, you're probably looking at something like this from Amazon:

https://www.amazon.com/Sifting-Classifier-Panning-Screens-Various/dp/B01N94HK75?tag=treasurenet01-20

Kevin is right that for basic panning, separating out the stuff that's larger than 1/8" (8-mesh) from the stuff that's smaller will help a lot. The idea with classifying is that you want to get similarly sized material in the pan together, so that as you do the panning action ("stratifying") the heavier gold will go deeper in the pan and the lighter material will be higher in the pan.

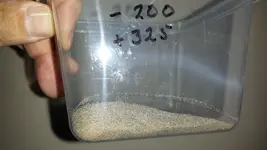

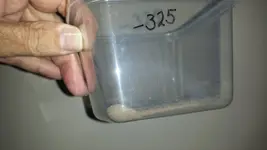

A kit like that one from Amazon helps to further classify out the different sized materials. When I sit down to "seriously" pan, I use most of those classifiers and then pan each individual size separately.

Also, if you're going to use stacking classifiers like those, it's

not super easy to stack them all up, pour the material in the top and run water through it. The stuff doesn't move down the stack very well. I find it's better to use one classifier at a time, working material through it into a pan, setting the stuff in the classifier aside (to be panned later), and then taking the material left over in pan and putting it in the next smaller classifier. Then repeat. You'll want at least 2 pans to do this, because there should be a pan under the next classifier when you pour material into it. It's slow, but it's precise - and that's important for flour gold.

If you're working with dry material the process may be different; I'm a wet guy.

- Brian

[emoji106]

[emoji106]

. You will yield more color per bucket if you try to concentrate it in the field.

. You will yield more color per bucket if you try to concentrate it in the field.