- Thread starter

- #21

You sir are the best! Thank you so much! I am awaiting the supplies!

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

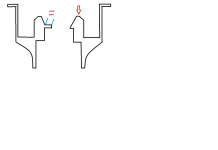

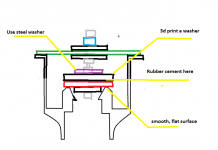

I got the plans from the US patent online and I just tried to replicate it.

Do you mean that the diaphragm worked better below the top level of the pulse valve? Or the water level with which part?