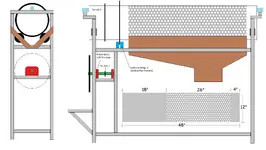

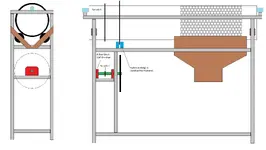

I have decided that its more important to have a longer wash area and a smaller classification area. For me its a no brainer. The entire idea is to wash the rocks clean before the rocks move onto the classification area of the cylinder. Anything larger goes out the end of the cylinder while everything smaller than 1/2" will be deposited into the sluice. The cylinder will be ready for me to pick up once I am back from Las Vegas. I am having the cylinder rolled from 11 gauge mild steel and the finish cylinder will have over five hundred 1/2" holes. Also my latest drawing will have the 6.5HP engine mounted under the cylinder instead of being mounted on the side of the trommel. Again this seems more logical as in this design its free of the dirt being placed in the hopper while making the entire trommel shorter due to having a removable hopper. Trommel will have a metal spray bar through the cylinder.

JeromeAz your concern of the weight but I will tell you the weight of the lid of the enclosed trommel will outweigh an open top trommel with a metal spray bar through the cylinder. Even the author and builder has stated that he dislikes having the spray bar on the outside of the cylinder. Spraying from the outside through the mesh just cannot wash the rocks at the same level as being washed with the spray bar on the inside. Jog is craftsman and his build is top notch, I just don't like having the spray nozzles spraying through the mesh.

View attachment 822436