Jeff95531

Silver Member

- Joined

- Feb 10, 2013

- Messages

- 2,625

- Reaction score

- 4,094

- Golden Thread

- 0

- Detector(s) used

- Teknetics Alpha 2000

- Primary Interest:

- Prospecting

I started a project this week and I wanted to post what's happened so far...before the FOG syndrome sets in.

OK, so last year I buy a shrimp gun from a local going outta business hardware store for half off ($20). Modify it for 5 bucks to collect gold. It handles like an Army Bazooka but first time using it, I find a .045 gram picker!! It's my first and I'm sold! So...now...I want to take it to the next level. Like pumping without losing anything. Like pumping into an in-stream sluice, a bucket or a pan directly via 1 inch hose...would be so much easier. But first...a little background.

It's my first and I'm sold! So...now...I want to take it to the next level. Like pumping without losing anything. Like pumping into an in-stream sluice, a bucket or a pan directly via 1 inch hose...would be so much easier. But first...a little background.

Performance of original configuration of shrimp gun as adapted for gold recovery:

Pros: 6' overall length. 1 inch intake for deep cleaning. Quiet. Crayfish hunting is a definite alibi. Disturbs only what I want, where I want and water is instantly returned as it flows out of the Super Sluice pan for con collection. Reaches where I can't.

Cons: Dumps rapidly at the end of each stroke as no check valve..at all. Adapt by pulling less and raising sooner but still a PITA. An angled intake (45/90) would help but still a major PITA (and not in direct point of contact with bottom as you can rarely see while operating it anyway. Also, the last most precious thing you sucked up will be the first thing to dump out on the ground on it's way to the pan or bucket soooo. And the same thing as a pro is a con as I had to shorten it to 5'2" as new hardware made it as tall as me! 6"2. Did it work? At first. With 2 check vales and straight water? You could flood a place real quick. BUT...Kinda no too. Suction is provided by a wafer Styrofoam-like freeze plug style (obviously need to upgrade it to a leather "seat cushion" wrap around...maybe even chamois?.) IDK

With both styles of check valves (cone @ intake with 1/2 pound spring pressure and a HD flapper valve at exhaust...and if I work up a sweat... it pulls some...with valves partially blocked open with -1/2" rocks...ugh.

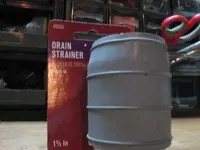

Here's some pics as I stumble my way thru the process. I have 2 types of check valves. A flapper for the exhaust to the bucket that I connected so as to expel all water but retain heavies but alas, -1/2 intake was MUCH too BIG for them as both valves opened, stuck and failed. So...1/8 inch screened before entering is much more realistic. Which means...I gotta come up with a shot glass style end for the intake to filter out all cept for -1/8. Or an X with a couple of bolts in the 1 inch intake

Results were less than spectacular. I mean, once I got the second (exh) check valve in place, it pumped water out like a fire truck. Solids tho? Not so much. How do I know this? Watching them in a clear hose race back and forth as I stroked. And nothing but black sand in the recovery bucket. Already $50 into it. More as this story develops...

More as this story develops...

The second check valve made all the difference...till I added rock to the slurry...

A bigger badder bucket and my poor mans BGT which the gun WILL eventually feed.

A bigger badder bucket and my poor mans BGT which the gun WILL eventually feed.

OK, so last year I buy a shrimp gun from a local going outta business hardware store for half off ($20). Modify it for 5 bucks to collect gold. It handles like an Army Bazooka but first time using it, I find a .045 gram picker!!

It's my first and I'm sold! So...now...I want to take it to the next level. Like pumping without losing anything. Like pumping into an in-stream sluice, a bucket or a pan directly via 1 inch hose...would be so much easier. But first...a little background.

It's my first and I'm sold! So...now...I want to take it to the next level. Like pumping without losing anything. Like pumping into an in-stream sluice, a bucket or a pan directly via 1 inch hose...would be so much easier. But first...a little background.Performance of original configuration of shrimp gun as adapted for gold recovery:

Pros: 6' overall length. 1 inch intake for deep cleaning. Quiet. Crayfish hunting is a definite alibi. Disturbs only what I want, where I want and water is instantly returned as it flows out of the Super Sluice pan for con collection. Reaches where I can't.

Cons: Dumps rapidly at the end of each stroke as no check valve..at all. Adapt by pulling less and raising sooner but still a PITA. An angled intake (45/90) would help but still a major PITA (and not in direct point of contact with bottom as you can rarely see while operating it anyway. Also, the last most precious thing you sucked up will be the first thing to dump out on the ground on it's way to the pan or bucket soooo. And the same thing as a pro is a con as I had to shorten it to 5'2" as new hardware made it as tall as me! 6"2. Did it work? At first. With 2 check vales and straight water? You could flood a place real quick. BUT...Kinda no too. Suction is provided by a wafer Styrofoam-like freeze plug style (obviously need to upgrade it to a leather "seat cushion" wrap around...maybe even chamois?.) IDK

With both styles of check valves (cone @ intake with 1/2 pound spring pressure and a HD flapper valve at exhaust...and if I work up a sweat... it pulls some...with valves partially blocked open with -1/2" rocks...ugh.

Here's some pics as I stumble my way thru the process. I have 2 types of check valves. A flapper for the exhaust to the bucket that I connected so as to expel all water but retain heavies but alas, -1/2 intake was MUCH too BIG for them as both valves opened, stuck and failed. So...1/8 inch screened before entering is much more realistic. Which means...I gotta come up with a shot glass style end for the intake to filter out all cept for -1/8. Or an X with a couple of bolts in the 1 inch intake

Results were less than spectacular. I mean, once I got the second (exh) check valve in place, it pumped water out like a fire truck. Solids tho? Not so much. How do I know this? Watching them in a clear hose race back and forth as I stroked. And nothing but black sand in the recovery bucket. Already $50 into it.

More as this story develops...

More as this story develops...

The second check valve made all the difference...till I added rock to the slurry...

A bigger badder bucket and my poor mans BGT which the gun WILL eventually feed.

A bigger badder bucket and my poor mans BGT which the gun WILL eventually feed.

Last edited:

Upvote

0