PickAxeCA

Jr. Member

- Nov 1, 2018

- 42

- 124

- Detector(s) used

- Barely a weekend warrior. Hard rock + placer together = a more complete sampling picture for AU.

- Primary Interest:

- Prospecting

There are plenty of people (Doc from Gold Hog, Vo Gus, etc) who claim that the majority of their gold is caught in the pooling area where water falls into the top end of a highbanker. I have heard some claims of 80-90%+ being caught up there.

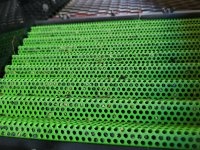

With this in mind, what are all the magical properties of a *small section* of punch plate over miner's moss (backed, or unbacked with V matting underneath) that cause such strong gold capture in the area with falling flow?

Here are my thoughts:

1. Friction - coarse gold gets snared in the moss (this is obvious)

2. Additional classification (also obvious)

3. Downward hydraulic pressure - 'pins' gold to the bottom, forcing it to burrow down even further.

4. One way ticket - once gold has sunk under the punch plate, the non-perforated parts (solid sheet) is a vertical barrier. Plus, water falling through holes will not let the gold rise upward again.

5. Reduces water and material speed

6. Diffuses flow - spreads out water, creates a more even flow, reduces surging, reduces turbulence and lifting force

7. Breaks surface tension - gold cannot rise up to ride on the surface tension

8. Creates a fluid bed (elutriation / gravity column) - if a reverse ramp riffle is used on the downstream end

----

What are your thoughts on punch plate or a diffuser at the top of a highbanker or sluice, and its impact on capture rates?

Are there any magical gold-catching properties that I have missed?

Let's talk about all the uses for punch plate when it comes to sluicing / highbanking.

Note - I'm sure many of you have heard about the Jarvie / Jarvine riffle (punch plate folded like an accordion). I wonder if it has unique properties that make it more effective than normal punch plate for capturing gold.

With this in mind, what are all the magical properties of a *small section* of punch plate over miner's moss (backed, or unbacked with V matting underneath) that cause such strong gold capture in the area with falling flow?

Here are my thoughts:

1. Friction - coarse gold gets snared in the moss (this is obvious)

2. Additional classification (also obvious)

3. Downward hydraulic pressure - 'pins' gold to the bottom, forcing it to burrow down even further.

4. One way ticket - once gold has sunk under the punch plate, the non-perforated parts (solid sheet) is a vertical barrier. Plus, water falling through holes will not let the gold rise upward again.

5. Reduces water and material speed

6. Diffuses flow - spreads out water, creates a more even flow, reduces surging, reduces turbulence and lifting force

7. Breaks surface tension - gold cannot rise up to ride on the surface tension

8. Creates a fluid bed (elutriation / gravity column) - if a reverse ramp riffle is used on the downstream end

----

What are your thoughts on punch plate or a diffuser at the top of a highbanker or sluice, and its impact on capture rates?

Are there any magical gold-catching properties that I have missed?

Let's talk about all the uses for punch plate when it comes to sluicing / highbanking.

Note - I'm sure many of you have heard about the Jarvie / Jarvine riffle (punch plate folded like an accordion). I wonder if it has unique properties that make it more effective than normal punch plate for capturing gold.

Last edited:

Upvote

2