DizzyDigger

Gold Member

- Dec 9, 2012

- 6,347

- 12,869

- Detector(s) used

- Nokta FoRs Gold, a Gold Cube, 2 Keene Sluices and Lord only knows how many pans....not to mention a load of other gear my wife still doesn't know about!

- Primary Interest:

- Prospecting

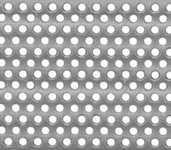

In the process of making a new, top mounted classifier for my

Gold Cube. Key part of it is a 6" section of 1/8" punch plate,

but I can't find a pattern or template on the web, anywhere.

Any ideas on a drill pattern for this? I know some of you have

drilled out the holes for your trommels, so how did you figure

out what pattern to drill by?

Gold Cube. Key part of it is a 6" section of 1/8" punch plate,

but I can't find a pattern or template on the web, anywhere.

Any ideas on a drill pattern for this? I know some of you have

drilled out the holes for your trommels, so how did you figure

out what pattern to drill by?

Amazon Forum Fav 👍

Upvote

0