- Jan 11, 2011

- 1,086

- 1,397

- Detector(s) used

- Minelab Manticore, Minelab Equinox 800, Minelab Equinox 600, Minelab CTX 3030

- Primary Interest:

- Metal Detecting

Hi all.

Now that I have the prototype shafts built, and will be ordering parts -- within days -- for the first production batch of shafts, I've been able to work some more on the counterweight design, and I have moved very close to finalizing the design.

I have discovered through this extensive testing/design that the amount of weight needed to achieve proper counterbalance is a bit more than I was originally thinking, after the preliminary, "rough" proof-of-concept testing. I would like to present the findings, and get some opinions -- from anyone who has been potentially interested in the counterbalance system -- as to whether these changes are acceptable, or if this would change your desire to possibly purchase the counterweights.

1. The weight needed to counterbalance the 12" x 15" coil, (based on an "average" lower rod extension length), is roughly 28 oz. This is a fairly substantial amount of weight -- BUT -- I must note that when the weight is applied, the machine swings BEAUTIFULLY. It FEELS lighter, even though the "absolute weight" -- i.e. according to measurement as provided by a scale -- is obviously greater. With my forearm in the arm in the arm cuff, swinging the machine normally, I was literally able to hold the handle of the machine with only my thumb and index finger -- and swing the machine effortlessly! The sensation is that the machine FLOATS across the ground! (For the 11" coil, the amount of counterweight needed is of course slightly less -- roughly 25 oz.)

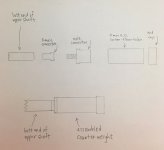

2. To include this amount of weight in the tube extensions, and yet not have the extensions excessively long, I must use larger-diameter carbon-fiber tube than I planned -- I've decided on 31mm outside diameter tubes. I had intended to use the same diameter of tubing as used on the upper shaft (22.15mm outside diameter), but the extension length required was far too long.

3. Using the 31mm outside diameter tube for the counterweights, I calculate that length of the tube extending beyond the end of the shaft will be 7 1/2" for the 12" x 15" coil, and 6 1/2" for the 11" coil.

4. There would be no changes to the shaft design needed; anyone wanting the counterweight system in the future would still purchase a shaft with the same threaded female fitting installed in the butt end of the shaft, and the same threaded end cap that screws into the butt end. The only changes would be to the counterweights themselves (as comparted to what I had originally planned) -- i.e. larger diameter carbon-fiber tubing, and thus a larger end cap for the ends of the counterweights themselves.

SO, my questions are, with the counterweight lengths needed now a pretty-well "known quantity" -- i.e. 6 1/2" and 7 1/2" long (11" coil and 12" x 15" coil, respectively), and the weights to achieve balance being also a pretty-well "known quantity" -- i.e. 25 oz. and 28 oz., respectively, would those interested in the weights find these specs acceptable? Please offer your comments.

Preliminary/rough pricing info would be as follows. One counterweight, $22.50 plus shipping ($30 total). If an EQX user only wanted to order one weight, I would suggest the 6 1/2" long, 25 oz. weight, designed for the 11" coil; this amount of counterweight still achieves a degree of balance that feels GREAT with the 12" x 15" coil. I am of the opinion that no counterweight is needed, for the 6" coil. Two counterweights, one for the 11" coil and one for the 12" x 15" coil, $42.50 plus shipping ($50 total).

Thoughts?

Steve

Now that I have the prototype shafts built, and will be ordering parts -- within days -- for the first production batch of shafts, I've been able to work some more on the counterweight design, and I have moved very close to finalizing the design.

I have discovered through this extensive testing/design that the amount of weight needed to achieve proper counterbalance is a bit more than I was originally thinking, after the preliminary, "rough" proof-of-concept testing. I would like to present the findings, and get some opinions -- from anyone who has been potentially interested in the counterbalance system -- as to whether these changes are acceptable, or if this would change your desire to possibly purchase the counterweights.

1. The weight needed to counterbalance the 12" x 15" coil, (based on an "average" lower rod extension length), is roughly 28 oz. This is a fairly substantial amount of weight -- BUT -- I must note that when the weight is applied, the machine swings BEAUTIFULLY. It FEELS lighter, even though the "absolute weight" -- i.e. according to measurement as provided by a scale -- is obviously greater. With my forearm in the arm in the arm cuff, swinging the machine normally, I was literally able to hold the handle of the machine with only my thumb and index finger -- and swing the machine effortlessly! The sensation is that the machine FLOATS across the ground! (For the 11" coil, the amount of counterweight needed is of course slightly less -- roughly 25 oz.)

2. To include this amount of weight in the tube extensions, and yet not have the extensions excessively long, I must use larger-diameter carbon-fiber tube than I planned -- I've decided on 31mm outside diameter tubes. I had intended to use the same diameter of tubing as used on the upper shaft (22.15mm outside diameter), but the extension length required was far too long.

3. Using the 31mm outside diameter tube for the counterweights, I calculate that length of the tube extending beyond the end of the shaft will be 7 1/2" for the 12" x 15" coil, and 6 1/2" for the 11" coil.

4. There would be no changes to the shaft design needed; anyone wanting the counterweight system in the future would still purchase a shaft with the same threaded female fitting installed in the butt end of the shaft, and the same threaded end cap that screws into the butt end. The only changes would be to the counterweights themselves (as comparted to what I had originally planned) -- i.e. larger diameter carbon-fiber tubing, and thus a larger end cap for the ends of the counterweights themselves.

SO, my questions are, with the counterweight lengths needed now a pretty-well "known quantity" -- i.e. 6 1/2" and 7 1/2" long (11" coil and 12" x 15" coil, respectively), and the weights to achieve balance being also a pretty-well "known quantity" -- i.e. 25 oz. and 28 oz., respectively, would those interested in the weights find these specs acceptable? Please offer your comments.

Preliminary/rough pricing info would be as follows. One counterweight, $22.50 plus shipping ($30 total). If an EQX user only wanted to order one weight, I would suggest the 6 1/2" long, 25 oz. weight, designed for the 11" coil; this amount of counterweight still achieves a degree of balance that feels GREAT with the 12" x 15" coil. I am of the opinion that no counterweight is needed, for the 6" coil. Two counterweights, one for the 11" coil and one for the 12" x 15" coil, $42.50 plus shipping ($50 total).

Thoughts?

Steve

Amazon Forum Fav 👍

Last edited:

Maybe just use a rubber end cap instead of a glued-on one? Most of us that beach hunt, have tons of lead to use, so, just the can would be all we would need.

Maybe just use a rubber end cap instead of a glued-on one? Most of us that beach hunt, have tons of lead to use, so, just the can would be all we would need.