TheForSaken

Jr. Member

- Apr 25, 2016

- 31

- 37

- Primary Interest:

- All Treasure Hunting

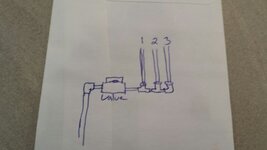

So after my headerbox failed to perform with satisfactory results, I ended up picking up a bunch of pvc tubing, connectors and a ball valve.

Whipped up together this manifold highbanker fitted for my prospector.

Unfortunately we've been getting rain everyday here so haven't had a chance to field test it as of yet.

Feeling comfortable that this design will perform better than my previous attempt at highbanking my bazooka. Hoping that having complete control of the flow for the fluid bed and separate control for the upper slick plate will be a winner.

I'll be running a 190 GPM pump, anyone with experience with this type of setup?

As soon as I can make it out, I'll post up vids.

Whipped up together this manifold highbanker fitted for my prospector.

Unfortunately we've been getting rain everyday here so haven't had a chance to field test it as of yet.

Feeling comfortable that this design will perform better than my previous attempt at highbanking my bazooka. Hoping that having complete control of the flow for the fluid bed and separate control for the upper slick plate will be a winner.

I'll be running a 190 GPM pump, anyone with experience with this type of setup?

As soon as I can make it out, I'll post up vids.

Plus Id leave the washers out for max flow to each valve /PSI gauge !!

Plus Id leave the washers out for max flow to each valve /PSI gauge !!